© John R. Bentley 2007.

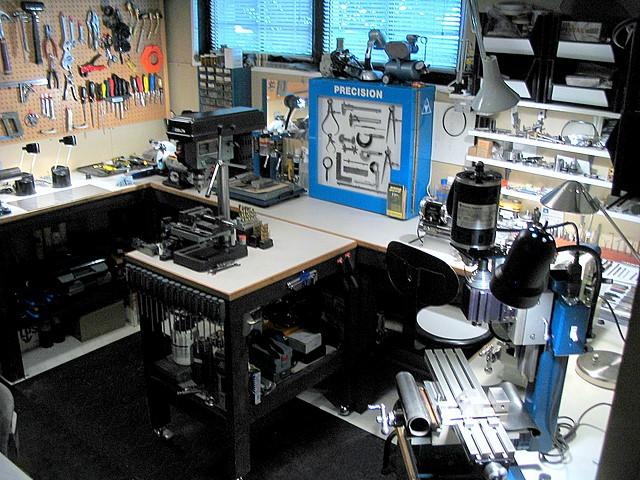

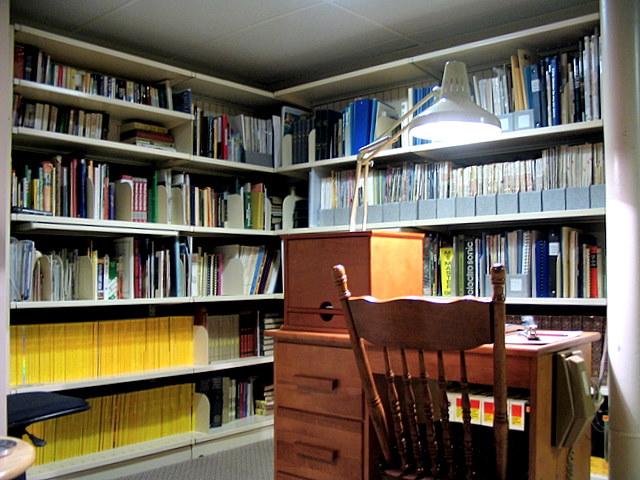

The NE corner of the workshop

September, 2007.

Workshop Pictures

from

© John R. Bentley 2007.

The NE corner of the workshop

Note that things constantly change in my workshop and pictures quickly become dated. Since this was taken, the blue coolant tray has been removed from the Craftex lathe on the right and the Taig lathe (straight ahead) has been replaced with a nearly identical new model, now powered by a motor with a Pulse Width Modulated DC supply. (Don't worry, you can rest assured the twenty-year-old original Taig and its Dayton motor still look and function like new!)

A Lomo MBC-10 (LF-100) Stereo Microscope attached to the Taig lathe for more exacting jobs.

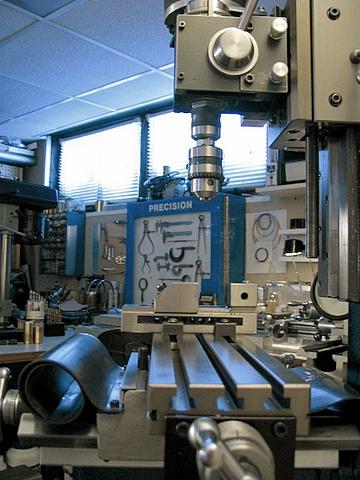

ALSO CHANGED: my Taig mill is now equipped with the optional ER-16 spindle and new head extrusion.

This picture was made before that change and shows the standard head with my quick-connecting drilling attachment.

I'm very happy with the Taig mill. In fact I found it very successful for precision drilling to the extent I felt I could replace the small drill press below with one of substance. This gives better precision when making large holes due the the sturdier structure and the momentum of the more massive rotating assembly.

The Craftex 7 X 8 lathe beyond the old drill press

As mentioned above, the small 8" bench drill has been replaced by a much larger machine with a CVT (continuously variable transmission).

- However I have left the old pictures here as they help explain the layout.

For the record, here is the new drill:

I hope to do a short page on the machine in the near future.

The drill press is mounted on a section of the bench that can be wheeled away on castors. This allows drilling very long awkward pieces (such as 8 or 12-foot lumber, pipes, etc) by removing the section from the workshop entirely. It also allows better use of the long section of benchtop which consequently is exposed along the window wall.

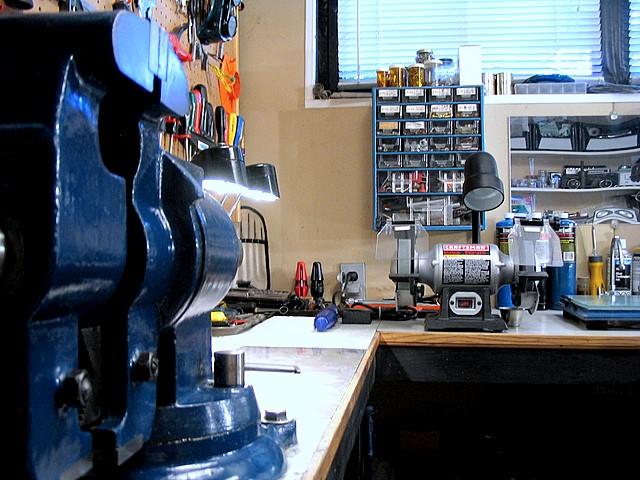

Looking over the DC-powered Taig lathe toward the double pegboard cabinet.

(the large round black dial left of the vise is an 8-inch diameter 0-300 psi steam pressure gauge)

The pegboard splits in the middle to reveal storage for silver brazing supplies and other small tools and spares.

Clearly the vise is larger than a 6" bench grinder.

Craftsman grinder dead ahead with a green carbide-grinding wheel on the left mandrel.

Screwdrivers are probably the most used tools in any workshop

Oh yes - some metal stock is handy too!

I am leaning more toward using hex stock in all materials these days as it grips positively in a 3-jaw chuck - most important when threading. It is also very useful in making nuts, bolts and valve bodies requiring some area of hex section in their design.

An original Dazor three-tube illuminated magnifier.

French curve and a new Taig pulley design "under glass"

The Lomo MBC-10 Stereo Microscope ready for inspection and assembly work on the bench.

For lots more information on this microscope and my setup Click Here

This old-style laptop is easily programable in BASIC for math jobs and has a boot-up time less than a second.

I frequently use this laptop when I need quick answers while machining.

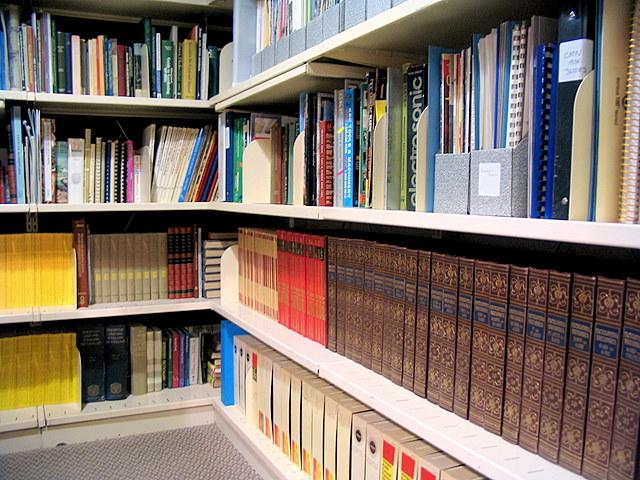

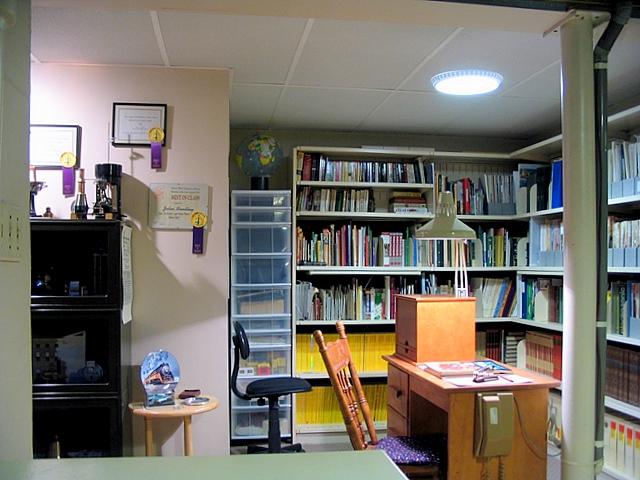

This reference section of my work area is adjacent to the workshop

it contains drawings, catalogs and numerous reference books..

In the foreground is a limited Coronation Issue of the 14th edition of the Encyclopædia Britannica. It dates from 1937 and contains magnificient drawings, engravings and photographs. In addition to revealing innumerable things, including the lost art and architecture of pre-WWII Europe, it has provided me valuable pieces of information about engine and boiler design. It is a much treasured resource.

This tiny library is a comfortable place with good lighting, a couple of chairs and two pull-out steel shelves in the racks.

The computers are located in other areas, allowing this to be a pleasant refuge from the modern world.

A glass display cabinet for some of my smaller models is on the left in this picture.

For a final shot - how about a fisheye view of the counter!

Back to the Workshop main page